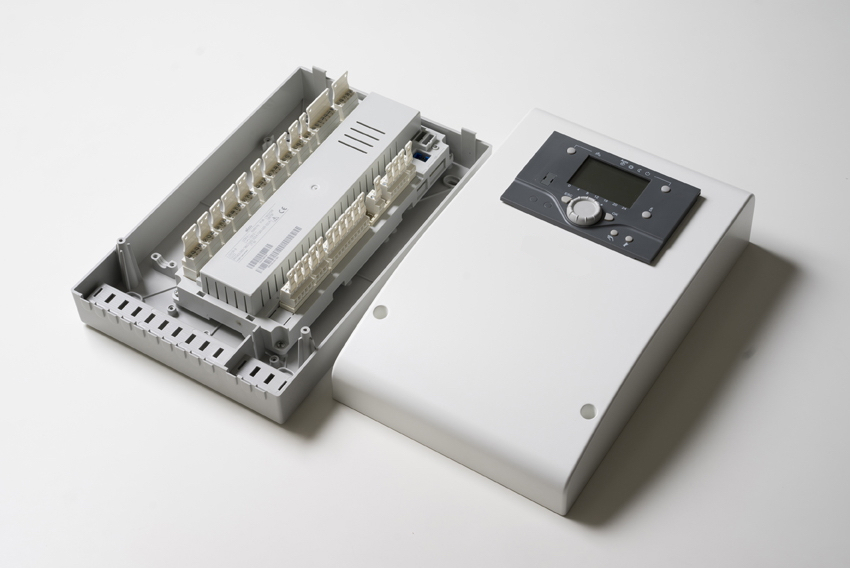

Technical moulding

Highest attention to the material and the specific Outline Dimensional Drawings.

All the machine features CNC and are individually equipped with manipulators for the extraction of pieces and mould temperature control units, so as to ensure the utmost reproducibility of the production cycle.

Quality is guaranteed by the use of modern machinery for the dimensinal and shape control of the moulded pieces.